Comfort navigation settings

The following information will provide you with an easy to navigate overview of what will happen with your personal data when you visit this website.

Ilapak wants to increase market shares and get the leadership in IQF protein and vegetables, produce and cheese industries and all of them have very strict hygienic requirements. In fact, the market out there is getting more and more sensitive to hygiene and all those industries require tough design specifications in order to avoid product accumulation and bacteria-harboring as well as harsh washdown procedures with aggressive detergents and high pressure.

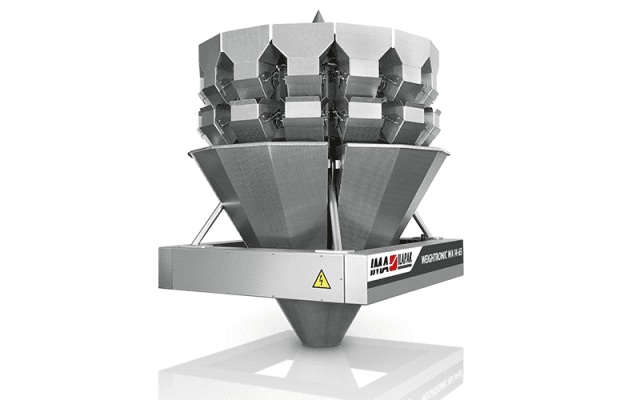

Fresh and IQF products are among IMA Ilapak main strategic industries (ie. fresh-cut salad, IQF protein and vegetables, cheese) and at the same time, they are among the most demanding food applications in terms of hygiene and indeed very challenging for the weighing systems and the packaging machines.

We all know how sensitive the market out-there has become to hygienic requirements in order to prevent infections to the end-users and now more than ever we all understand how easily infection can spread and lead to serious effects.

This is why it is vital that the complete packaging line going from the conveyors transporting naked product, the weigher and the bagging machine is fully capable to withstand the washing procedures, detergents and sanitizers the market requires today. In fact, only a few global players are ready to do so, and Ilapak is among them.

So to make sure all machines going into harsh environments are properly tested before they leave the IMA Ilapak factory has just built up a washdown room where both weighers and packaging machines can be washed down and cleansed according to the specific market requirements.

IMA Ilapak washdown room is a 5m x 5m x 6m (WxDxH) closed room with clear windows on 3 sides equipped with automatic spray ball and nozzles to apply a number of sanitizing detergents specifically required by those industries and high-pressure rinsing (over 100bar/1,450psi).

The main target is testing any piece of new equipment dedicated to markets requiring sanitation before leaving the factory.

Also, we want to show and prove to our customers the real capability of our machines and weighers to withstand the harsh environment and detergents they require.

With the same philosophy in 2019 IMA Ilapak Italia had built up a cold room where the complete packaging line can be set up and run any kind of fresh product at the same temperature and humidity as the real packaging room.

In fact, both packaging machines and multi weigher can be positioned in our washdown room and sanitized according to the specifical required procedures, detergents and pressure.

So today IMA Ilapak has moved another step forward to let its customer touch with hand what IMA Ilapak can propose for a packaging solution, ready to run the real product and film at the required room conditions in the cold room, the same packaging system can be additionally demonstrated in the washdown room according to the same procedures and detergents applied in the “real world”. We believe this can all be a tremendous sales-tool showing our full commitment to quality.

Fill this form to be always updated about Ilapak’s world